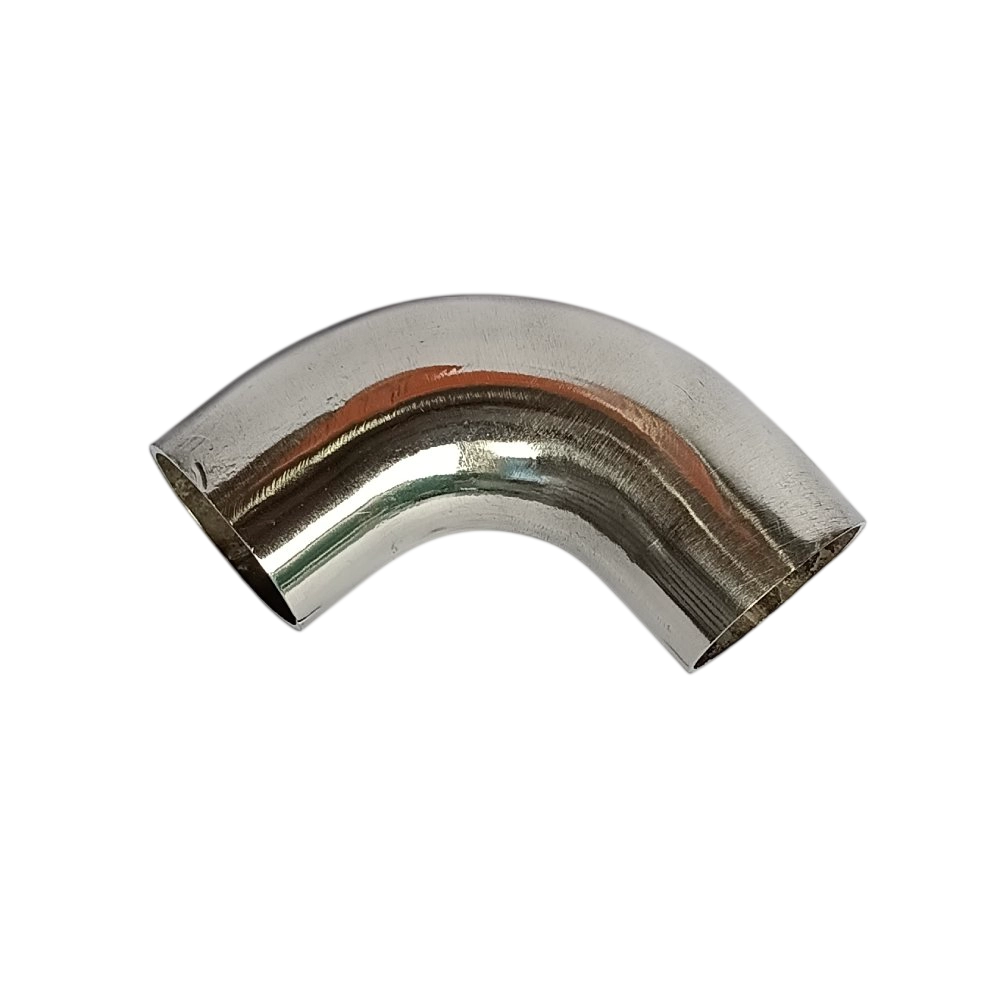

PSH123 Dairy Bend is a molded hygienic rubber component designed for smooth directional flow in dairy and food processing pipelines. It offers flexibility, sealing efficiency, and vibration absorption while maintaining hygiene standards. Manufactured from food-grade elastomers, it resists wear, temperature variations, and cleaning chemicals.

PSH123 Dairy Bend is a high-quality elastomer pipeline component engineered for sanitary and food-grade fluid handling systems. Its curved design allows smooth change in flow direction while minimizing turbulence and pressure loss. The component ensures leak-proof performance and vibration absorption in dairy and hygienic processing lines.

Manufactured using food-grade EPDM, Silicone, or other approved elastomers, this dairy bend provides excellent resistance to temperature fluctuations, steam cleaning, and common sanitizing chemicals. The material is non-toxic, odorless, and compliant with hygienic processing requirements.

Its flexible structure accommodates slight misalignment and movement in pipelines, reducing stress on joints and extending system life. The smooth internal surface supports easy cleaning and prevents residue buildup, which is essential in dairy and food applications.

Key Features:

- Hygienic and food-grade material options

- Smooth internal surface for better flow

- Flexible and vibration absorbing

- Resistant to cleaning chemicals and steam

- Leak-proof and durable design

Applications:

Used in dairy plants, milk processing units, beverage industries, food production lines, and sanitary fluid transfer systems where cleanliness, flexibility, and reliability are essential.